Bethlehem Steel played a larger role than just producing steel.

The technological advancements that Bethlehem Steel made throughout the late 19th century allowed it to push past its competitors and form a corporate monopoly over the rail industry. This corporate monopoly enabled Bethlehem Steel to facilitate development of new towns in the region as well as urban centers. This story shows that development happened far outside of the Bethlehem Steel plant, along with inside of it.

The timeline below depicts the technological advancements made by Bethlehem Steel in the late 19th century. This series of events enabled the growth of Bethlehem Steel as a company, followed by its growth throughout the country.

How Bethlehem Steel Grew

Bethlehem Steel was the only corporation that was able to adapt to changing market conditions to outlast other iron mills in the Lehigh Valley when the British started producing steel and exporting it to Pennsylvania railroads. Bethlehem Steel had successfully produced enough rails that it could afford to switch to integrated production, a form of production that combined iron blast furnaces, steel furnaces, and rolling mills into one plant. Integrated production enabled Bethlehem Steel to produce more rails and structural steel beams for cheaper. The more rails and structural beams Bethlehem Steel produced, the more widespread its influence was. More rails meant more railroads, and more structural beams meant more buildings. More railroads meant more steel and workers could be transported to growing cities, such as New York City.

How Rails Were Made

There were three main innovations in how rails were produced at Bethlehem Steel.

- In the late 19th century, most iron plants used a two-high mill, where two sets of rolls were stacked on top of each other to roll iron into rails. This mill caused many delays because the steel had to cool between each roll. John Fritz adopted technology from Wales and introduced Bethlehem Iron to the three-high mill, which could roll iron into T-shaped rails while it was still hot. The three-high mill was more efficient than the two-high mill and enabled Bethlehem Iron to produce more iron rails than its nearby competitors.

A diagram of the two-high mill. - When Bethlehem Iron became Bethlehem Steel in 1899, it adopted the Bessemer process. The Bessemer process involved a furnace blowing air through molten pig pronto heat it and remove carbon until it reached the right proportion of carbon to air to make it steel. Without the incorporation of the Bessemer process, Bethlehem Steel may not have become the corporate monopoly that it was. This process was crucial to the beginning of mass production of steel that was cheaper than iron. Steel was stronger and safer for rails.

- Integrated production, as mentioned above, allowed Bethlehem Steel to more easily produce steel in mass quantities and produce larger steel beams and rails. It combined a blast furnace with a steel furnace followed by rolling mills, and was crucial for the stability of Bethlehem Steel’s corporate monopoly of the rail industry along with the structural steel industry. The steel produced through integrated production is what Bethlehem Steel is most commonly known for, such as skyscrapers and bridges, but the rails made through this process also were important to the expansion of railroads.

The Influence of Bethlehem Steel

With the expansion of railroads, towns began developing along railroads since they provided easy transportation for people and products. As these towns developed, they used steel from Bethlehem Steel to create buildings. Many skyscrapers including the Flatiron Building and American International Building in New York City were made from Bethlehem Steel. The railroads made from Bethlehem Steel were also important in not only transporting material, but also transporting workers across the country. The railroads brought in new immigrants from countries such Poland and Hungary to work at Bethlehem Steel, so as Bethlehem Steel expanded regionally, it also continued to grow as a corporate monopoly.

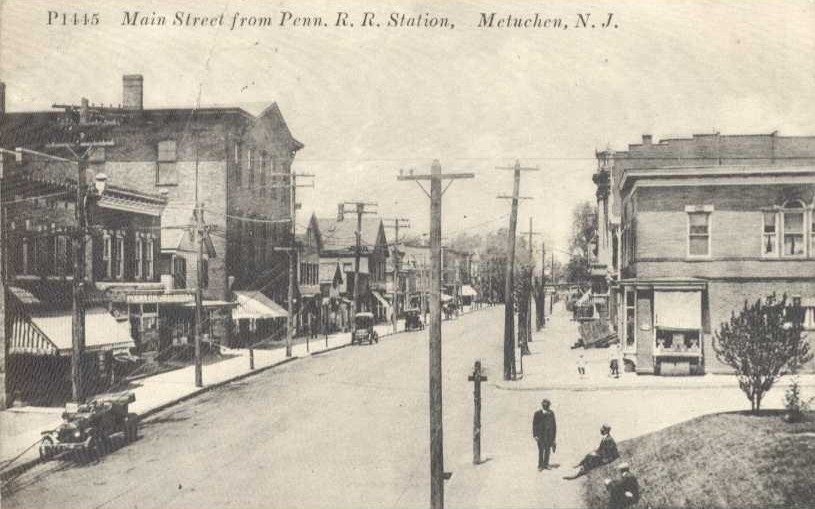

Metuchen, New Jersey, is an example of a smaller town that Bethlehem Steel played a key role in the development of. Metuchen originated alongside the Pennsylvania Railroad, but was quickly followed by the Lehigh Valley Railroad. Many towns similar to Metuchen were developing along railroads since they provided easy transportation for people and products. The railroads that ran through Metuchen brought Irish and Italian laborers and their families to Metuchen, which is close enough to New York City that workers could commute daily via train. In the two blocks around the train station, dozens of small stores, two banks, and a movie theater were built. The Lehigh Valley Railroad was crucial to the development of Metuchen and many other towns.

Page created by Claire

.jpg/250px-Bessemer_Converter_(PSF).jpg)