1. Summarize and report out on the results of the SKS exercise.

When talking amongst each other about our team dynamics, we identified things we want to “Start”, “Keep”, and “Stop.”

Start

- Holding ourselves and each other accountable for the tasks we commit to. It can be difficult to ask your peers to contribute more (or less), and to communicate this constructively. By improving upon this skill, we will collectively accomplish more and advance the project forward more quickly.

- Setting clear objectives with dates. Our team has done a good job so far of setting objectives for the end of the semester and identifying weekly goals necessary to meet these objectives. However, adding more deadlines throughout the semester to ensure appropriate progress is being made will help us stay on track and avoid going in circles.

- More team bonding! By spending time together outside of project meetings, we will have a better idea of the strengths and weaknesses of our team members, outside of an academic setting. This will help us to avoid the functional fixedness bias.

Keep

- Being open, honest, and willing to ask for help. Our team has done a good job so far about being honest and open with the rest of the team about when we are having a particularly challenging week and are unable to contribute to our normal extent. By communicating this honestly, it allows the entire team to adjust their expectations and objectives for the week accordingly.

- Being enthusiastic about the project. Each member of our team has different but similar motivations for joining the project. We all share a similar level of enthusiasm that is helpful for encouraging each other when we face adversity.

- Divide and conquer tasks to reach the desired end goal. This team is unique in that we have diverse majors and skill sets. By allowing team members to take responsibility for tasks they are passionate about and have experience with, we ensure that all tasks are completed well.

Stop

- Waiting until the last minute to complete assigned tasks. As we are all busy and have different schedules, sometimes a lack of communication results in leaving tasks to the last minute. If nobody is able to start an assignment until the day before it is due, we are not able to complete it to the quality that we could have if we started earlier. By communicating more clearly about a timeline for individual assignments, all of our work will be done to a higher quality.

- Going around in a loop, as it slows progress and lowers morale. This is tied to our goal to start setting clearer mid-semester goals to act a progress marker.

2. Develop a detailed Collaboration Plan for your team clearly articulating your Goals (Small g and Big G), Roles,Procedures, and Relationships.

Goals

What are the personal goals (small g) of each member on this team?

- Laura: Use the technical skills I’ve developed through my coursework at Lehigh to make positive change on global scale

- Susan: To change the way people currently live to be more sustainable and environmentally friendly through my mechanical engineering and product design background.

- Kelly: Using my experience to manage the distribution channels of plastics to ensure there is consistency in the types of plastics used, so that the bricks ultimately can be of high quality to the population of the Philippines.

What is the Project GOAL (big G) we’re all committed to achieve together?

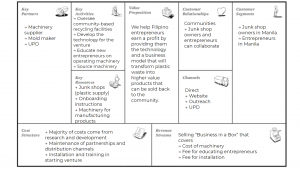

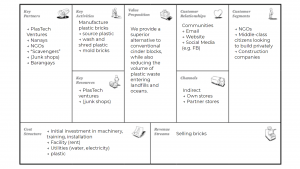

- To divert solid plastic waste from landfills and prevent plastic pollution in the oceans

Is our Project Goal scaled to our resources (dreams, materials, skills, differences, etc.) and constraints (assignment, time, skills, etc.)

- No, the project goal is extremely massive (the entire country), which is the size of our dreams. However, with our current resources we are not ready to change the entire country all at once. Therefore we are taking little steps, starting with a small community in Manila, where we are able to more effectively apply the skills and knowledge of a five member team from all different backgrounds to not only combat the plastic crisis but to also develop a business opportunity for Filipinos living in poverty. Scalability will be assessed at a later stage in the project.

What are the metrics for success for what we’re producing?

- Pounds of solid recycled plastic waste diverted

- Quantity of products made from recycled plastics

- The number of women employed

- The number of entrepreneurs who adopt our business model

- The number of junk shops who adopt our business model

Roles

Who is responsible for which deliverables?

- Paper on compressive strength of recycled PET

- Paper on junk shops

- Wall system prototype and machinery design

- Manufacturing Process

Which deliverables that require collaboration, subgroups & individual work? Who does each person depend upon to succeed?

- All the deliverables will require some sort of collaboration with at least another team member. For the wall system design and prototyping, Susan will be leading the effort with Andy supporting her. Andy will be incharge of redesigning the machinery with Susan and Ellie providing support along the process. Kelly will be conducting the supply chain and junk shop investigation with side support from the entire team. Laura will be conducting testing on the compressive strength of recycled plastics (with different contamination levels) over the summer at mountaintop and Kelly will be assisting her in the effort.

Do we need a project manager to coordinate?

- The team has been coordinating well with each other. At the end of every meeting we determine the next steps that are required to progress the project and delegate the tasks according to people’s assigned role on the team. Each member thus far has done a good job in completing their tasks by the deadline.

What are the deliverables each person is accountable to produce?

- Laura: Research results and a written paper on the compressive strength of recycled plastics at different contamination levels.

- Susan: Develop 3 wall system design, produce prototypes of wall system, create building block in solidworks for FEA

- Andy: Develop mold for wall system, develop machinery needed to produce the wall system, fabricate the machinery

- Ellie: Develop the manufacturing process plan to produce the building block

- Kelly: Develop the financial model and supply chain of the recycling business

Procedures:

Decision Making – What process shall we use: consensus, majority rules, deference to expert, default to the loudest, or?

- Decision making will result from mainly a team consensus.

Effective Meetings – Focus on key, timely decisions together vs. status/update (offline);

- Meetings occur every Friday where each team member presents their work for the past week. The team analyzes the result of all the team members work and determines the next steps as a group. The team then divides and conquers the tasks needed to achieve the next steps by the next week deadline.

Meeting roles: scribe, facilitator, time keeper

- The team rotates on being the scribe. The team goes around one by one on the work they have done to further the project. Brian acts as the facilitator and asks key questions to push the team forward.

Communication – FTF: frequency, time, location; type of technology: (Googledocs, Zoom, Hangout, etc.); expectations for responsiveness; ‘best time to work’ (AM, PM, weekends?)

- The general meeting between the team, advisors, PI, and sponsors occur on Fridays from 11am-12pm on Zoom. The team communicates with each other through Slack anytime of the day and expects a response whenever another team member reads the message.

Relationships

Team Diversity – What is the diversity on our team? Disciplines to tap for solutions; individual learning styles for the stages of invention; overall team learning style strengths and places to supplement; cultural backgrounds , work experience, dreams to leverage for scope & impact of goals, new roles, better procedures; languages for more diverse customer set, bigger market;

- Currently our team is composed of people from all kinds of backgrounds that has contributed to advancing the PlasTech Venture forward. First, the majority of the team is pursuing a different major. Andy and Susan are mechanical engineering majors (Susan is also pursuing a product design minor) and have been really involved in making various designs of wall systems and the machinery to produce the wall systems. Ellie is an ideas major (mechanical engineering and environmental studies) who has been investigating UV degradation on plastics to understand how the wall systems will be impacted by the sun over a long period of time. Laura is a material science engineering major who will be conducting research on the pressive strength of recycled plastics at different contamination levels. Lastly, Kelly is a supply chain major and is playing a major role in determining the movement of plastics in the Philippines.

Listening – Notice my binary thinking, auto-rankism, and go beyond it.

- When developing different designs of the wall system, the team brainstormed and sketched designs for a week. During the Friday meeting of sharing all the designs that were created, the team provided critics on the designs and took best practices from each other. The team listens closely to each other’s ideas and provides feedback/ideas to advance the project forward. If the team were to run into binary solutions, we would split into two and investigate the two solutions in order to gather information for the team to consensually agree on the best solution.

Team Name–What’s a team name that captures who we are and what we’re going to do?

PlasTech Ventures! The team is utilizing technology to create products out of recycled plastics in order to diverge plastics from the landfill and ocean. The business model that the team is currently developing will provide entrepreneurial opportunities to Filipinos.