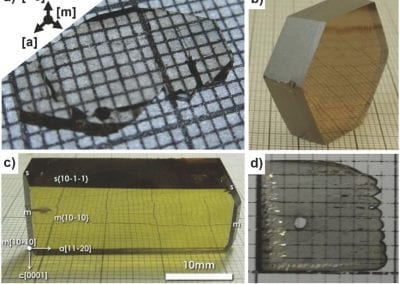

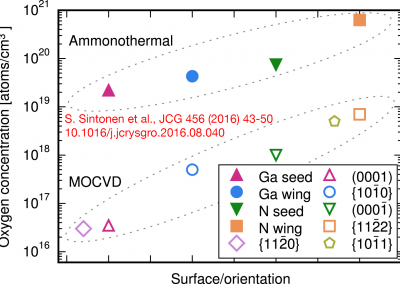

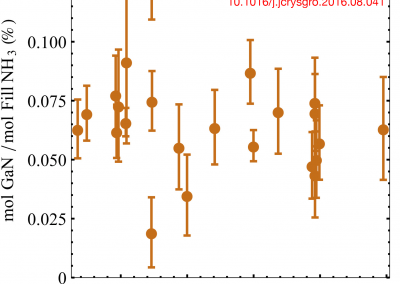

Incorporation and effects of impurities in different growth zones

within basic ammonothermal GaN

Journal of Crystal Growth, 456 (2016) 43-50

DOI: 10.1016/j.jcrysgro.2016.08.040

Funding: Academy of Finland (12297916), Aalto Energy Efficiency Programme, SSLEEC, MRL (DMR 1121053)

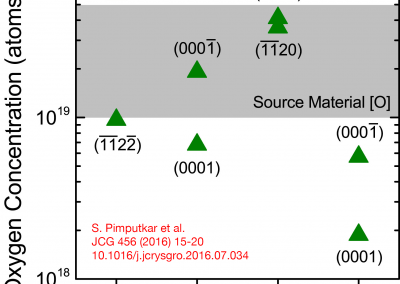

The ammonothermal method is one of the most promising candidates for large-scale bulk GaN growth due to its scalability and high crystalline quality. However, emphasis needs to be put on understanding the incorporation and effects of impurities during growth. This article discusses how impurities are incorporated in different growth zones in basic ammonothermal GaN, and how they affect the structural, electrical and optical properties of the grown crystal. The influence of growth time on the impurity incorporation is also studied. We measure the oxygen, silicon, and carbon impurity concentrations using secondary ion mass spectrometry, and measure their effect on the lattice constant by high resolution x-ray diffraction (HR-XRD). We determine the resulting free carrier concentration by spatially resolved Fourier transform infrared spectroscopy and study the optical properties by spatially resolved low-temperature photoluminescence. We find that oxygen is incorporated preferentially in different growth regions and its incorporation efficiency depends on the growth direction. The oxygen concentration varies from 6.3×1020 cm−3 for growth on the {112-2} planes to 2.2×1019 cm−3 for growth on the (0001) planes, while silicon and carbon concentration variation is negligible. This results in a large variation in impurity concentration over a small length scale, which causes significant differences in the strain within the boule, as determined by HR-XRD on selected areas. The impurity concentration variation induces large differences in the free carrier concentration, and directly affects the photoluminescence intensity. (Read full text)