Welcome to the Reichmanis Group! We are currently immersed in the expansive realm of organic/hybrid functional materials, delving into advancing technologies for organic electronics, sustainable energy applications, multifunctional organic/inorganic hybrid optoelectronics, and bioelectronics. A central theme of our research involves establishing interrelationships between performance, processing, and materials structure. Spanning the fields of chemical engineering, chemistry, and materials science, our group’s multi-disciplinary endeavors have fostered collaborations across various departments and faculties at Lehigh, Georgia Tech, and other leading institutions. Examples of current projects include:

- Design, synthesis and development of organic mixed conductors and processes for flexible, stretchable bioelectronics applications.

- Design and development of materials systems for sustainable alternative energy applications, spanning from energy conversion to energy storage.

- Design of colloidal quantum dot (QD) processing approaches to enable solution-processable and large area production of QLEDs and other optoelectronic devices

- Design and develop data science guided experimental approaches to enable elucidation of process-structure-property relationships in solution processed conjugated polymers toward flexible electronics

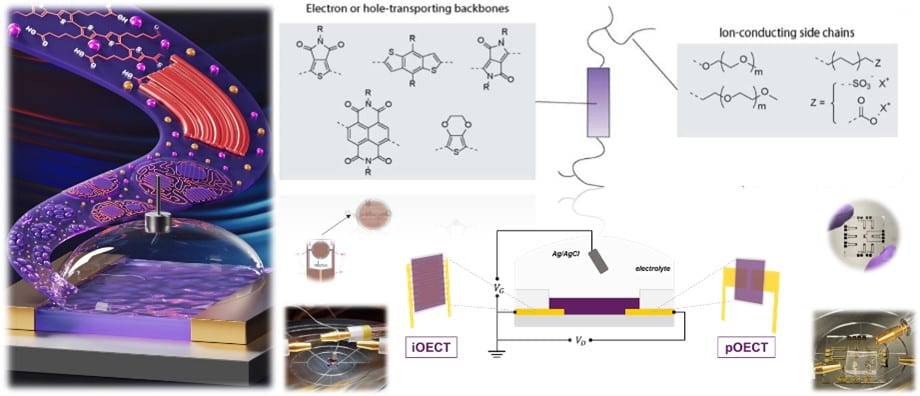

Organic mixed conductors and organic electrochemical transistors. (10.1021/acs.chemmater.3c02103)

Our research focuses on a distinctive class of polymers that efficiently and simultaneously conduct electronic charges and transport ions. Known as organic mixed ionic-electronic conductors (OMIECs). They emerge as promising candidates in the realm of organic bioelectronics due to their unique mixed conduction properties. When incorporated into an organic electrochemical transistor (OECT) they exhibit multiple advantages for sensing applications – they can amplify biological signals at low-operating voltages while maintaining high fidelity, and the flexible, wearable nature of these devices enhances their versatility for diverse applications. To fully realize their potential, our group explores on the complex array of characteristics aiming to identify clear structure-function relationships so that the promise of OMIECs can be realized. Through many advanced and time resolved characterization techniques, we merges synthetic development, fundamental structure-property relations, and integration into electrochemical devices to inspire the development of high-performance mixed-conduction materials for applications ranging from sensors to energy storage to light-emitting electrochemical cells and transistors to neuromorphic devices.

Surface engineering of electrode materials and electrode design for high-performance lithium-ion batteries. (10.1039/D3CC05608B)

Batteries, essential for powering a myriad of portable electronic devices, have become a cornerstone of modern technology. Our research group is at the forefront of enhancing these storage devices, focusing on the electrode – a key component where the interfacial interactions of materials is

crucial for energy output and battery lifespan. Traditional electrode materials often struggle to meet the growing performance demands due to poor interfacial properties between electrode material components. Investigating batteries from a holistic perspective, we engage in the synthesis of novel electrode materials and the innovation of electrode formulations, aiming to concurrently enhance and optimize battery performance from multiple perspectives. Our approach develops composite electrodes that are a leap forward in terms of performance and durability and the developed integrated systems significantly outperform traditional, empirically developed composite battery electrodes. Looking ahead, as we delve further into how the physicochemical interactions between high-capacity active materials and their surrounding environment affect electrochemical performance and begin to understand the origins of SEI layer formation, more clues for developing high-energy-density, high-power systems with stable performance will emerge. A deeper understanding of the mechanisms will undoubtedly pave new pathways for further enhancing performance, which is crucial for realizing the next generation of lithium-ion batteries.

Large-area production of solution processed colloidal quantum-dot light emitting diodes.

Quantum dot-based light emitting diodes (QLEDs) are attractive candidates for next-generation displays due to their high efficiency, brightness, wide color gamut, and solution processability. Large-scale production of QLEDs poses significant challenges, particularly concerning the precise control of the active layer’s thickness and uniformity. These obstacles directly impact charge transport, leading to current leakage and reduced overall efficiency. Blade-coating is a prevalent and scalable solution processing technique known for its speed and minimal waste. Additionally, it allows for continuous “roll-to-roll” processing, making it highly adaptable in various applications. We focus on all-solution-processed QLEDs, utilizing blade-coating to create the QD emissive layer, investigating the relationship between processing parameters, thin film structure, and device performance to gain new insights. In addition to our process oriented research, we are exploring the design and integration of QD emission layers with organic/polymer semiconductors to enhance QD emission efficiency by improving the charge carrier balance and suppress QD photoluminescence quenching.

Elucidation of Process-Structure-Property Relationships in Conjugated Polymers via Integration of Data Science and Experimental Approaches. (10.1021/acsmaterialslett.1c00320)

Conjugated polymers exhibit tremendous potential for advancing next-generation electronics, owing to their unique attributes, including solution processability, mechanical properties (such as flexibility and stretchability), and suitability for large-area printing. Realizing this potential necessitates advancements not only in polymer chemistry but also in polymer processing techniques. Our research focuses on establishing comprehensive relationships between the polymer’s structure, processing methods, and resulting properties to optimize device performance. We employ an innovative approach that combines data science with experimental methodologies. This integration allows us to significantly economize on both resources and time compared to traditional methods. Our research employs techniques for characterizing polymer behavior in solution and solid-film states, as well as assessing device electrical performance. These data serve as the foundation for employing data science techniques to identify critical process-structure-property relationships. The insights gained through data science analyses aid in guiding the direction of subsequent experiments, while the data generated from these experiments enable more precise and informed data science modeling in subsequent steps. Through synergistic use data science and experimentation, we illuminate the intricate process-structure-property connections, accelerating the development of next-generation electronics.