Characterization of Heterogeneous Colloidal Gel Systems

Graduate students: Matthew Wehrman (PhD ’18) and Shiqin He (PhD, expected ’22)

Collaborator: Seth Lindberg (Procter & Gamble Co.)

Publications:

- D. Wehrman, S. Lindberg and K. M. Schultz*, “Multiple particle tracking microrheology measured using bi-disperse probe diameters,” Soft Matter, 14, 5811 – 5820, 2018.

- D. Wehrman, M. J. Milstrey, S. E. Lindberg and K. M. Schultz*, “Impact of shear on the structure and rheological properties of a hydrogenated castor oil colloidal gel during dynamic phase transitions,” Journal of Visual Experiments, 134, e57429, 2018.

- D. Wehrman, S. E. Lindberg and K. M. Schultz*, “Impact of shear on the structure and rheological properties of a hydrogenated castor oil colloidal gel during dynamic phase transitions,” Journal of Rheology, 62, 437 – 446, 2018.

- D. Wehrman, M. S. Milstrey, S. Lindberg and K. M. Schultz*, “Using μ2rheology to quantify rheological properties during repeated reversible phase transitions of soft matter,” Lab on a Chip, 17, 2085-2094, 2017. Selected as a HOT article (top 10%)

- D. Wehrman, S. Lindberg and K. M. Schultz*, “Quantifying the dynamic transition of hydrogenated castor oil gels measured via multiple particle tracking microrheology,” Soft Matter, 12, 6463-6472, 2016.

Colloidal gels play a vital role in the stability of commercial products, such as shampoo and laundry de- tergent. The structure and properties of colloidal gels is dramatically changed by environmental conditions and these changes can cause decreases in shelf life and unexpected performance of the product. The goal of this work is to traverse the environmental parameter space creating a toolbox of measurement and analysis techniques that quantify dynamic colloidal gel rearrangement, degradation and het- erogeneity to enhance product design, development and manufacturing.

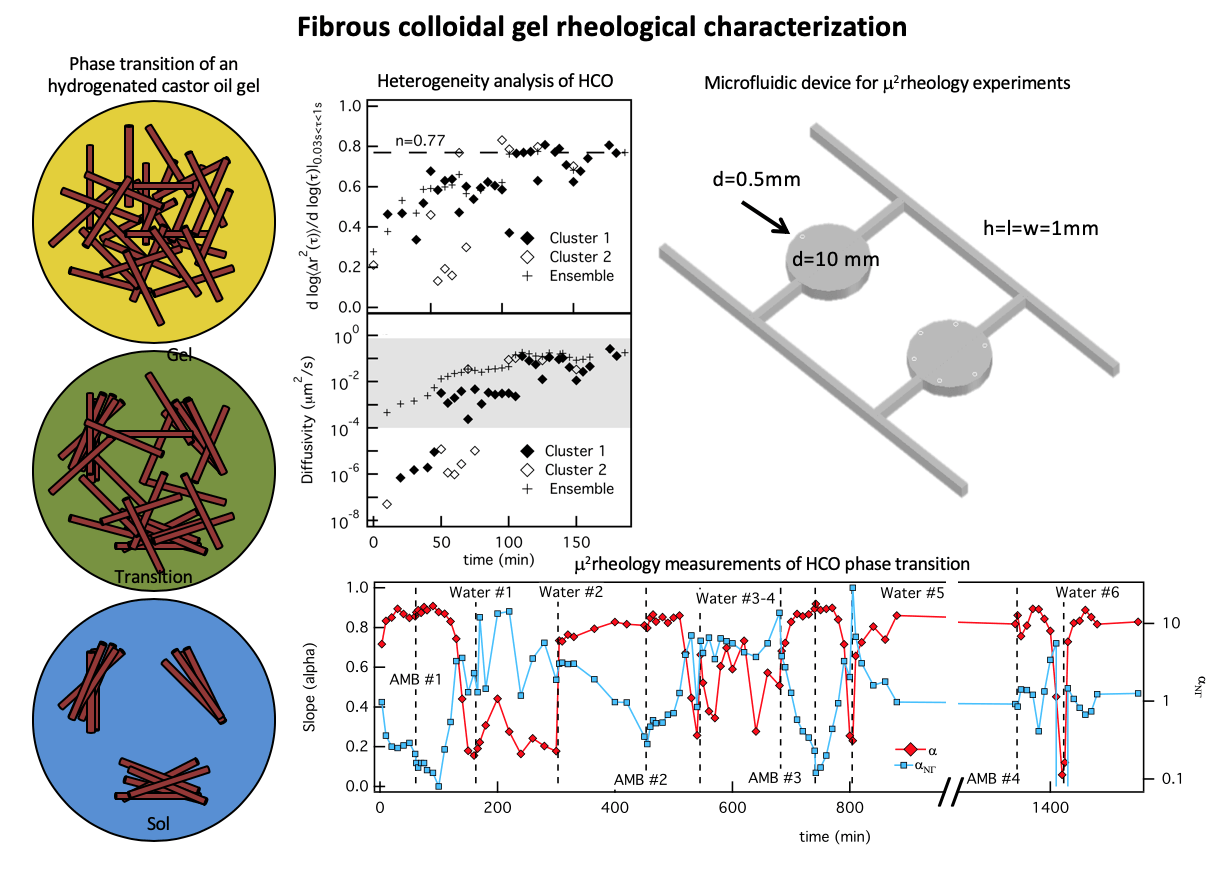

In this work, we characterize the dynamic, heterogeneous degradation and gelation of a hydrogenated castor oil (HCO) gel. The gel consists of HCO fibers with surfactant crystallized along them, water, and an environmental surfactant, linear alkylbenzene sulfonate (LAS). The surfactant that surrounds the crystals drives bundling, and in the aqueous suspension this results in a depletion interaction between fibers which forms a stable gel that does not undergo gravitational collapse. The gel goes through phase transitions in response to an osmotic pressure gradient made by contacting the scaffold with either water or a water-starved hydrophilic liquid. In this work, we have developed new analysis techniques that maximize information from measurements of heterogeneous scaffold microenvironments. Material properties are determined from the mean-squared displacements (MSDs) of probe particles temporally during transitions. This data is analyzed using time-cure superposition to determine the critical transition time and critical relaxation exponent, which identifies the structure at the phase transition. Next, spatial and rheological heterogeneities are quantified. We determine that scaffold heterogeneity does not significantly change MPT measurements but heterogeneity analysis provides additional insight into the evolving microstructure as the scaffold undergoes critical transitions.

Time-cure superposition and heterogeneity analysis suggests HCO gels return to the same equilibrium properties after repeated phase transitions. But HCO samples that are prepared with and without shear have different critical relaxation exponents, indicating the structure of the materials are different. We developed a new microfluidic device that enables fluid exchange around the sample (even when it is a sol) by using pressure to ‘lock’ it in place. During solvent exchange around the sample, minimal shear is added to the material. After fluid exchange, MPT is used to characterize the scaffold. With this device we can induce several phase transitions on a single sample to determine whether colloidal rearrangement or shear added during sample preparation is responsible for the change in scaffold structure measured during single gelation and degradation experiments. These measurements confirm HCO returns to the same equilibrium properties after each phase transition, suggesting the addition of shear during sample preparation is changing the scaffold structure. Bulk rheological investigations of both gelation and degradation confirm that shear added during sample preparation changes the accessible material properties. From these studies, we find that processing prior to material use changes the rheological properties of this rheological modifier, which should be considered during manufacturing.