Lean Healthcare is the application of lean ideas in healthcare to minimize waste in every process, procedure, task through an ongoing system of improvement.

The concept of Lean was introduced by the Toyota Production System (TPS). Lean was based on five principles

What is lean according to the Toyota Way?

The Toyota Production System (TPS) is based on two main concepts:

- “Just-in-Time” which means only make what is needed, when it is needed and in the amount that is needed.

- This concept mainly relates to having a takt time( which is understanding how long will I need to make and assemble products so as to match my demand),

- have a continuous flow such that I have minimal inventory and

- have a system driven by a pull system ( which is production and delivery is based on demand)

- ” Jidoka” which means autonomation.

- This means that when an error is detected in the production line, the line is stopped, the abnormality is inspected, it is then fixed or corrected, and a root cause analysis is done and finally counter-measures are introduced.

- This ensures that the quality of the products are not compromised.

These two main concepts are the pillars to achieve the goals of delivering high quality products at low cost and the shortest lead time.

How can the concepts of lean be translated to healthcare?

The Lean concept introduced by Toyota can be adopted into healthcare.

- The “Just-in-Time” can be interpreted as providing the right service in the right amount at the right time in the right place; essentially eliminating undertreatment/ overtreatment and underuse/overuse of resources. Another aspect is to ensure continuous flow of supplies that will make sure the use of fresh supplies and prevent expiration of medical supplies.

- The other would be “Built in Quality“. This is important as it checks for quality issues. Any quality issue that is detected is assessed, analysed, corrected and immediately taken care of.

- Currently most of the healthcare system works on the push system wherein supply is not determined by demand. The lean method favours the use of a pull system wherein supply is determined by demand.

- Use of 5S and Visual Control – The 5S are Sort, Set in order, Standardize, Shine, & Sustain. The lean Visual Control uses color coded, easy to identify arrangements or instruction charts that can convey information at a glance improving patient care and help standardize control measures.

- Value Stream Mapping is another improvement method that lays out the processes and flow in a visual format.

What are the wastes in relation to healthcare?

Wastes in healthcare, is when efforts or expenses are expended but the patient or the consumer of healthcare is not receiving the benefits from the system in value to their expenses/efforts.

| Type of Waste | Examples in Healthcare |

| Defect |

|

| Overproduction |

|

| Waiting |

|

| Unused Talent |

|

| Transportation |

|

| Inventory |

|

| Motion |

|

| Extra Processing |

|

Applicability of Lean Thinking in Healthcare

The adoption of lean thinking in healthcare can improve the patient care experience, organizing existing processes , improving provider experience, can improve finances by spending only on what is required and prevent stalled resources immobilising money and infrastructure.

While lean improvement strategies implemented can be beneficial, there are some important points to consider for the success for a lean project. Lean thinking is a continuous process and has very little room for error. An organization using lean thinking has to embrace a culture and ensure that all their employees and processes are working according to the prescribed way at regular intervals for it to work.

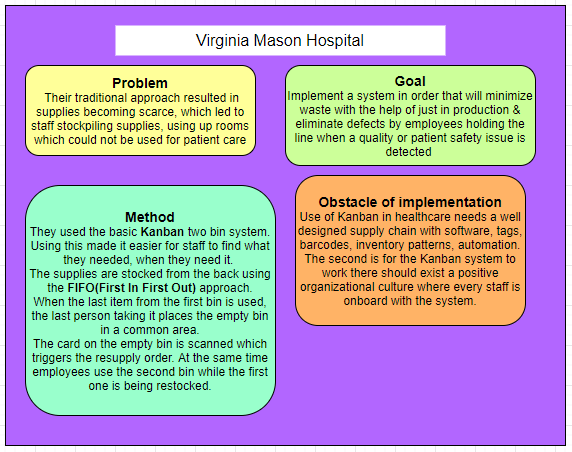

There have been quite a few healthcare organizations that have started using lean methods. One of the first hospitals to adopt the TPS was Virginia Mason Hospital in 2002.

References-

Kanban in Healthcare – a Way of the Future?