- (Elastohydrodynamic Lubrication) EHL Lubrication: In the EHL regime, for sliding of a smooth sphere on a soft solid, a ‘‘Hertz-like’’ effective contact region forms. Much of the fluid is squeezed out of the contact region although enough is retained to keep the solid surfaces fully separated. The behavior of such soft lubricated contacts is controlled by a single dimensionless parameter 1/beta that can be interpreted as a normalized sliding velocity. We solve the lubrication problem under Hertz limit and study how hydrodynamic pressure, film thickness and hydrodynamic friction vary with beta. Scaling laws for these relationships are given in closed form for a range of beta not previously accessible theoretically but that is typical in applications. The computational method can also be used to study other soft lubrication problems. H. Wu, N. Moyle, A. Jagota, C.-Y. Hui, Soft Matter 2020, 16, 2760.

- Two Phase Periodic Structure (TPPS) for Friction Enhancement: Typical mechanisms for controlling the sliding friction in lubricated conditions involve bulk material compliance, fluid viscosity, viscoelastic response of the material (hysteretic friction), and breaking of the fluid film where dry contact occurs (adhesive friction). We show that a two phase periodic structure, with a varying modulus across the sliding surface, provides significant enhancement of lubricated sliding friction when the system is in the EHL regime. We propose that the enhanced friction is due to extra energy loss during periodic transitions of the sliding indenter between the compliant and stiff regions during which excess energy is dissipated through the fluid layer. This is a form of elastic hysteresis that provides a novel mechanism for friction enhancement in soft solids under lubricated conditions. N. Moyle, H. Wu, C. Khripin, F. Bremond, C.-Y. Hui, A. Jagota, Soft Matter 2020, 16, 1627.

- Embedded Mesh Structure (TPPS) for Friction Enhancement: Controlling the lubricated sliding friction of compliant contacts is important for many mechanical and biological systems. Multiphase materials have been shown to exhibit varied lubricated friction responses when compared to controls of just one phase of the material. In this work, we describe a structured two-phase material composed of a plastic mesh embedded in a compliant elastomer matrix. EMS exhibits increased lubricated sliding friction for a number of load, velocity, and lubricant viscosity conditions. The observed friction enhancement appears to be a result of the EMS sample transitioning to the mixed lubrication regime under conditions in which the control is in the elastohydrodynamic lubrication regime. Simulations suggest that the difference in lubrication regimes for the EMS sample compared to the unstructured control comes from areas of high contact pressure induced by the increased local contact stiffness of the material near the embedded mesh. We hypothesize that these areas of high pressure can lead to the destabilization of lubricant films under conditions where the control films are stable, leading to the difference in lubrication regime behaviors observed. N. Moyle, H. Dong, H. Wu, C. Y. Khripin, C.-Y. Hui, A. Jagota, Tribol. Lett. 2022, 70, 2.

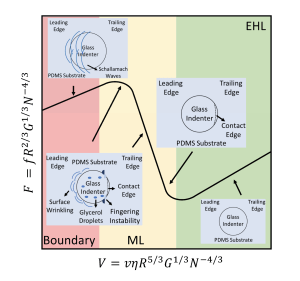

- Lubrication Regime Transition:Lubricated contacts in soft materials are common in various engineering and natural settings, such as tires, haptic applications, contact lenses, and the fabrication of soft electronic devices. Two major regimes are elasto-hydrodynamic lubrication (EHL), in which solid surfaces are fully separated by a fluid film, and mixed lubrication (ML), in which there is partial solid-to-solid con-tact. The transition between these regimes governs the minimum sliding fric-tion achievable and is thus very important. Generally, the transition from EHL to ML regimes is believed to occur when the thickness of the lubricant layer is comparable with the amplitude of surface roughness. Here, it is reported that in lubricated sliding experiments on smooth, soft, poly(dimethylsiloxane) substrates, the transition can occur when the thickness of the liquid layer is much larger than the height of the asperities. Direct visualization of the “contact” region shows that the transition corresponds to the formation of wave-like surface wrinkles at the leading contact edge and associated instabil-ities at the trailing contact edge, which are believed to trigger the transition to the mixed regime. These results change the understanding of what governs the important EHL–ML transition in the lubricated sliding of soft solids. H. Dong, N. Moyle, H. Wu, C. Y. Khripin, C.-Y. Hui, A. Jagota, Adv. Mater. 2023, 2211044.