A new system for sodium flux growth of bulk GaN.

Part I: System Development

Journal of Crystal Growth, 456 (2016) 58-66

DOI: 10.1016/j.jcrysgro.2016.07.044

Funding: KACST-KAUST-UCSB Solid State Lighting Program, SSLEEC, MRL (DMR 1121053)

Mohammed Abo Alreesh

Grad. Student, University of California, Santa Barbara

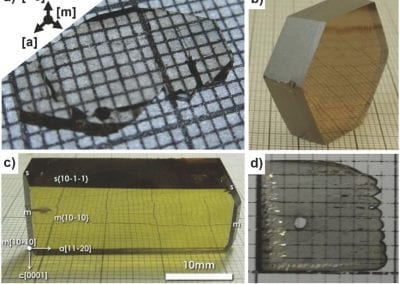

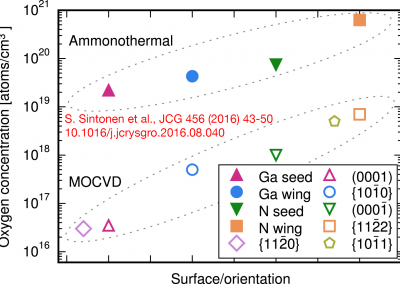

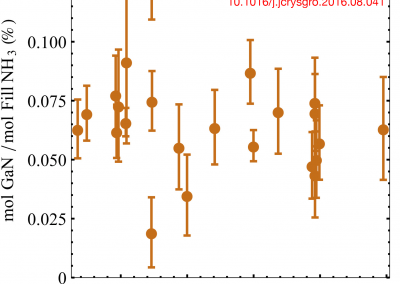

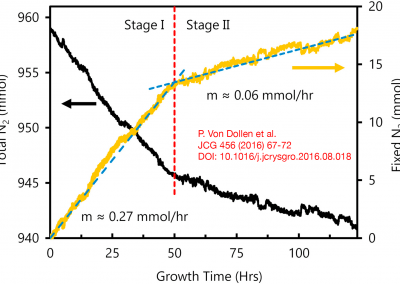

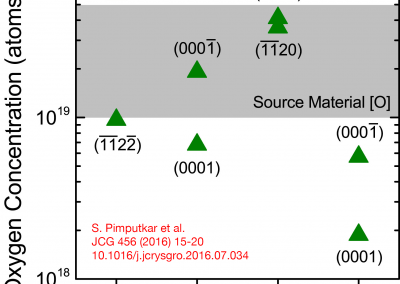

Though several methods exist to produce bulk crystals of gallium nitride (GaN), none have been commercialized on a large scale. The sodium flux method, which involves precipitation of GaN from a sodium–gallium melt supersaturated with nitrogen, offers potentially lower cost production due to relatively mild process conditions while maintaining high crystal quality. We successfully developed a novel apparatus for conducting crystal growth of bulk GaN using the sodium flux method which has advantages with respect to prior reports. A key task was to prevent sodium loss or migration from the growth environment while permitting N2 to access the growing crystal. We accomplished this by implementing a reflux condensing stem along with a reusable capsule containing a hermetic seal. The reflux condensing stem also enabled direct monitoring of the melt temperature, which has not been previously reported for the sodium flux method. Furthermore, we identified and utilized molybdenum and the molybdenum alloy TZM as a material capable of directly containing the corrosive sodium–gallium melt. This allowed implementation of a crucible-free system, which may improve process control and potentially lower crystal impurity levels. Nucleation and growth of parasitic GaN (“PolyGaN”) on non-seed surfaces occurred in early designs. However, the addition of carbon in later designs suppressed PolyGaN formation and allowed growth of single crystal GaN. Growth rates for the (0001) Ga face (+c-plane) were up to 14 µm/h while X-ray omega rocking (ω-XRC) curve full width half-max values were 731″ for crystals grown using a later system design. Oxygen levels were high, >1019 atoms/cm3, possibly due to reactor cleaning and handling procedures. (Read full text)